Knight Piésold Chile Pioneers the Application of BIM and AWP to Develop Mining Projects

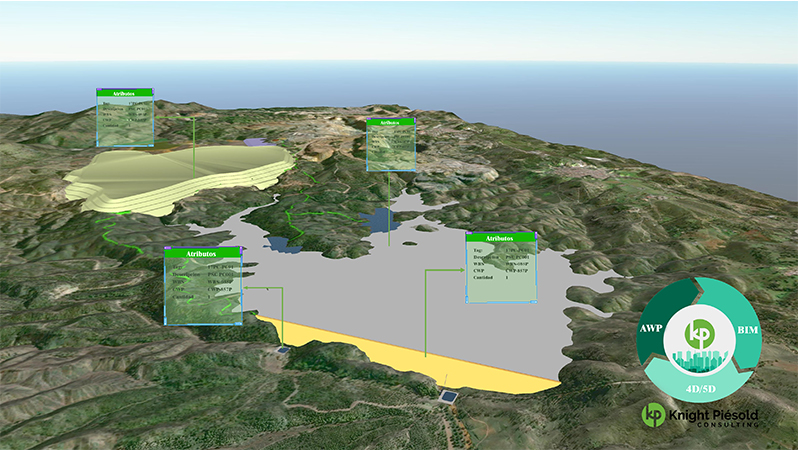

October 19, 2021, Santiago, Chile – Knight Piésold Chile has pioneered the application of the Building Information Modeling (BIM) and Advanced Work Packaging (AWP) methodologies for mining projects relating to tailings deposits. The company has successfully completed the engineering development of the IX Stage of the Talabre Tailings Management Facility (TMF) Construction Project—a significant milestone in the company’s continuous drive for innovation in developing mining projects.

The company started supporting Codelco Chile on the project’s pre-feasibility level design in 2018 and feasibility level design in 2020. The design involved the expansion of the perimeter walls of the Talabre TMF, with auxiliary and complementary works that allow operational continuity to the deposit while reducing CAPEX that was obtained in the pre-feasibility study by at least 20%. The project involved more than 130,000 person-hours of engineering design and served as the basis for the development of BIM and AWP methodologies at Knight Piésold Chile.

BIM, as a whole, refers to the collaborative process of creating and managing information for construction projects. It integrates all project information—from conception to completion—in a central information model created by all parties involved in construction and lifecycle management. Data and graph information are available at all times to be used as required.

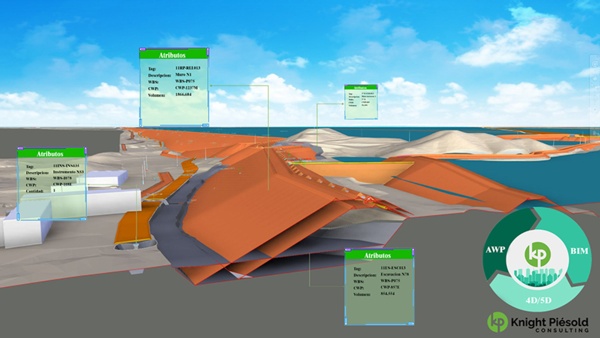

AWP, a work packaging process, involves aligning engineering work packages with procurement and construction development. The construction team is involved in the early stages to allow the engineering product to meet the requirements of the project in terms of quality, deadlines, and cost. The project is divided into manageable, well-defined pieces that can be executed, budgeted, measured, and controlled.

Through 3D model based workflows, BIM can be used as a visual planning tool, and through additional dimentions, that of time (4D BIM) and cost (5D BIM), BIM can be used for project management and cost control. The 4D/5D simulations are an example of the versatility of BIM and can show the construction sequence and estimate costs directly from the quantities of materials obtained from the BIM model. In addition, BIM can extend workflows to create virtual reality or augmented reality experiences, such as tours, personnel training, equipment assembly simulations, and many others.

“Our team uses the latest technology, such as Autodesk's AEC Collection suite and BIM360 platform, and has a solid structure for developing projects using the BIM methodology,” said Carlos Gómez, Project Leader and BIM Coordinator at Knight Piésold Chile. “We have developed BIM models in a collaborative manner, in sync on the Cloud, and with a focus on construction as the final objective—delivering engineering in the 21st century.”

Knight Piésold Chile is at the forefront in the application of BIM and AWP methodologies for engineering development and works toward expanding support to more mining tailings projects.