Lindero Gold Mine

Client

Mansfield Minera S.A., a subsidiary of Fortuna Mining Corp.Location

Salta, ArgentinaHighlights

- Topographic surveys, geotechnical assessments, seepage detection for the leach pad liner, geoelectrical evaluations of the leach pad, and puncture and interface testing on geosynthetics

- Detailed engineering for a staged construction approach for leach pad expansion

- Construction Quality Assurance and Project Construction Management

- Engineer of Record services

Overview

The Lindero Gold Mine is situated in the Puna region of Salta province, Argentina, at an altitude between 3,700 and 3,900 meters above sea level. Located south of Salar de Arizaro, near the town of Tolar Grande, the mine utilizes conventional heap leaching to extract ore at a nominal production rate of 6,750,000 metric tonnes per year.

The mine holds 1.284 million ounces of gold in proven and probable reserves, with an additional 412,000 ounces in measured and indicated resources and 386,000 ounces in inferred resources. With a projected average annual production of 101,238 ounces of gold, the mine has a remaining lifespan of 12 years.

Mansfield Minera S.A. (Mansfield), a subsidiary of Fortuna Mining Corp. (Fortuna), sought a strategic technical consultant to advance the start of production by the end of 2024. Knight Piésold provided full-cycle services, in alignment with the mine’s operational needs.

Knight Piésold’s comprehensive approach included:

- Opening an office in Salta to establish a strategic presence and maintain proximity during project execution, reaffirming the company’s commitment to the client and region.

- Providing detailed engineering for Phase 2 of the leach pad expansion that incorporated advanced criteria and a staged construction design, optimizing resources and effectively addressing the project’s challenges.

- Conducting interface and puncture testing on geosynthetics, verifying that materials used throughout different project phases met high-quality standards and compatibility requirements.

- Provided project construction management services that were fundamental in completing Phase 2 of leach pad expansion, providing efficient contract management, procurement, and planning. The on-site team maintained compliance with deadlines, quality standards, and cost controls.

The Challenge

Mansfield sought a strategic partner to develop the mine, a large-scale project requiring specialized services to optimize costs and maximize efficiency. Knight Piésold provided full-cycle services in alignment with operational needs that proved crucial to achieving this objective.

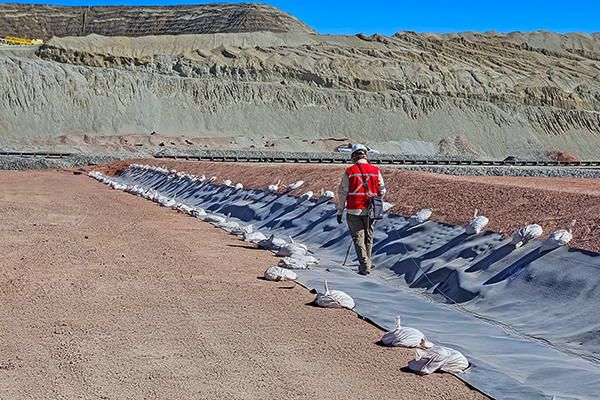

The initial phase spanned topographic surveys and various tests, including geotechnical tests, seepage detection using the Dipole method, geoelectrical tests on the leach pad, and puncture and interface tests with geosynthetics. The second phase comprised engineering services that upheld quality and efficiency in project technical development.

Knight Piésold’s services concluded with Construction Quality Assurance (CQA) and Project Construction Management (PCM) for Phase 2 of the leach pad expansion. Engineer of Record services were also provided to maintain rigorous control of the project’s macro-operations. This comprehensive approach allowed Mansfield to successfully address each project challenge to efficiently and sustainably develop the mine.

Our Approach

Knight Piésold, in close collaboration with Mansfield and Fortuna, played a crucial role in monitoring and managing the expansion of the leach pad. Knight Piésold was initially retained to conduct seepage detection programs on the leach pad liner and provide CQA services for Phase 1B construction.

Recognizing the need for expansion, Mansfield selected Knight Piésold as a strategic partner for PCM in Phase 2, developing detailed engineering for a staged construction approach divided into Phases 2A and 2B. This service included defining design criteria; designing civil, electromechanical, and piping systems; and developing capital expenditure plans.

Knight Piésold’s PCM services were instrumental in achieving Phase 2 of the leach pad expansion, enabling efficient contract management, procurement, and planning. Knight Piésold’s on-site team coordinated quality and cost controls, along with supervision activities, in compliance with the schedule, quality standards, and budget parameters established by Mansfield. This integrated approach enabled the successful completion of 490,000 m² of platform with no critical deviations.

This comprehensive approach demonstrates how Knight Piésold’s services aligned with the client’s strategy, delivering effective solutions and continuous support throughout project development.

The Results

The project achieved technical and strategic milestones, most notably the successful expansion of the leach pad in Phases 2A and 2B. The design rigorously complied with hydraulic, geotechnical, and civil criteria aligned with high industry standards. This optimization enhanced storage capacity while upholding system stability. Moreover, the implementation of advanced technologies, such as the Dipole and Vaten methods in the seepage detection and repair programs, secured the pad’s impermeability, minimizing operational losses.

As for infrastructure, Knight Piésold executed a comprehensive redesign of electromechanical systems, adapting the pumping facilities and a substation transformer to meet the project’s new energy demands, optimizing operational performance and energy efficiency.

These accomplishments not only solved complex technical challenges but also delivered additional benefits, including reduced operating costs, increased production efficiency, and optimized resources. This success demonstrates Knight Piésold's capacity to provide innovative, high-impact solutions to the mining industry.